Quality

Our quality control department performs all final inspection in-house by using CMM and Laser QC inspection equipment.

Aerospace Alloys, Inc. is:

ISO 9001 and AS9100 Certified

Pratt & Whitney LCS Approved

Aerospace Alloys, Inc. is committed to a high standard of material verification prior to any further processing. All incoming materials is subject to our XRF (x-ray fluorescence) Analyzer. This allows us to confirm mill material certifications and provide our customers with the assurance that the material they are getting is just what they ordered.

We are dedicated to continuous improvement

and customer satisfaction.

- All incoming material is checked by our XRF analyzer

- Blueprint review and quality requirements are analyzed on all jobs before production

- Laser QC for first article inspection

- Laser QC for SPC (Statistical Process Control)

- CMM (Coordinate measuring Machine)

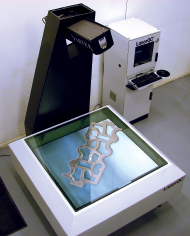

Laser QC

Laser QC

Laser QC is the automated, high-speed laser inspection system for first article inspection, Statistical Process Control (SPC) and reverse engineering of 2D parts. With the compatibility of dxf, .dwg and .igs file formats we can take any complex measurements quickly and easily.

(800) 214-0475 • sales@aalloys.com